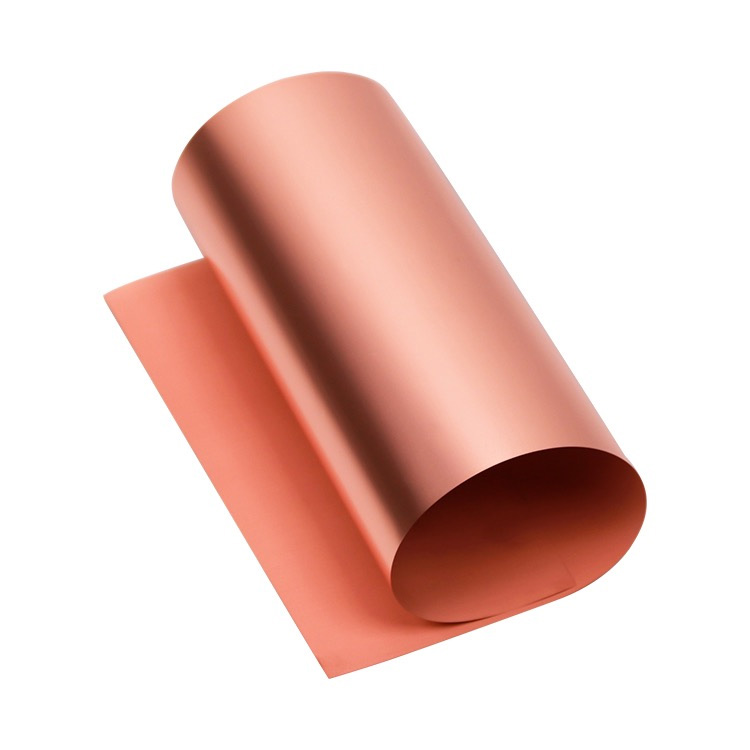

Double bò trete papye kwiv pou HDI

●Epesè: 12um 18um 35um 70um

●Lajè estanda: 1290mm, nou ka koupe kòm kondisyon gwosè

●ID: 76 mm, 152 mm

●Longè: Customized

●Echantiyon ka ekipman pou; Tan plon: 7days

●Tan livrezon: 15-20days

●Anbalaj Detay: ekspòtasyon bwat an bwa

●Tèm: FOB, CIF.

●Atik Peman: 50%T/T depo, balans peye anvan anbake.

●Ekipman pou jete pèfòmans segondè pèfòmans fè pwosesis fabwikasyon nan papye kwiv.

●Double-bò trete papye kwiv

●Avèk gwo fòs obligatwa pou Plastifye

●Laminasyon dirèk milti-kouch

●Bon etchability

●Papye a trete se woz

●Komisyon Konsèy Awondisman Multi

●HDI (segondè dansite entèrkonèkteur) pou PCB

| Klasifikasyon | Inite | Ekzijans | Metòd tès | ||||||

| Deziyasyon papye |

| T | H | 1 | 2 | IPC-4562A | |||

| Epesè nominal | um | 12 | 18 | 35 | 70 | IPC-4562A | |||

| Pwa zòn | g/m² | 107±5 | 153± 7 | 285 ± 10 | 585± 20 | IPC-TM-650 2.2.12 | |||

| Pite | % | ≥99.8 | IPC-TM-650 2.3.15 | ||||||

| Rsouness | Bò klere (RA) | um | ≤3.0 | IPC-TM-650 2.2.17 | |||||

| Bò ma (RZ) | um | ≤6 | ≤8 | ≤10 | ≤15 | ||||

| Fòs rupture | RT (23 ° C) | MPA | ≥207 | ≥207 | ≥276 | ≥276 | IPC-TM-650 2.4.18 | ||

| H.T. (180° C) | ≥103 | ≥103 | ≥138 | ≥138 | |||||

| Elongasyon | RT (23 ° C) | % | ≥2 | ≥2 | ≥3 | ≥3 | IPC-TM-650 2.4.18 | ||

| H.T. (180° C) | ≥2 | ≥2 | ≥2 | ≥3 | |||||

| Rezistivite | Ωg/m² | ≤0.170 | ≤0.166 | ≤0.162 | ≤0.162 | IPC-TM-650 2.5.14 | |||

| Peel fòs (FR-4) | S bò | N/mm | ≥0.9 | ≥0.9 | ≥1.4 | ≥1.4 | IPC-TM-650 2.4.8 | ||

| Liv/nan | ≥5.1 | ≥6.3 | ≥8.0 | ≥8.0 | |||||

| M bò | N/mm | ≥0.9 | ≥1.1 | ≥1.4 | ≥2.0 | ||||

| Liv/nan | ≥5.1 | ≥6.3 | ≥8.0 | ≥11.4 | |||||

| Pinholes & porosite | Nonbs | No | IPC-TM-650 2.1.2 | ||||||

| Anti-oksidasyon | RT (23 ° C) | Jou | 180 | / | |||||

| H.T. (200° C) | Minit | 40 | / | ||||||

Lajè estanda, 1295 (± 1) mm, lajè ranje: 200-1340mm. Me dapre kliyan an demann tayè.

PCB Copper Foil Imaj